Double Screw PVC Drain-Pipe Extruder Production Line

Product Description of PVC Drain-Pipe Extruder Production Line

Features of PVC pipe making machine extruder machine

1) It is mainly used in the manufacture of PVC pipes with various diameters and wall thickness in the aspects such as the agricultural and constructional plumbing, cable laying etc.

2) The set is composed of conical twin-screw extruder, vacuum cablibrating tank, haull-off, cutter, stacker or belling machine etc.

3) The extruder and haul-off machine adopt the imported AC frequency control device.

The vacuum pump and hauling motor employ superior goods.

4) Haul-off machine of different specifications, such as two claws, three claws, four claws, six claws etc are designed for different requirements.

5) It is additionally attched with length measuring apparatus and thickness increasing device.

6) The unit is of reliable performance and high production efficiency.

The pipe diameter is mainly from Φ 16mm-Φ 630mm. We also can design the machine according to your requirement

Main parameter of PVC pipe making machine extruder machine

| Extruder model | SJSZ-50/105 | SJSZ-55/110 | SJSZ-65/132 | SJSZ-80/156 | SJSZ-92/188 |

| Driving motor (kw) | 15 | 37 | 37 | 55 | 90 |

| Pipe diameter range(mm) | 16-40 | 20-110 | 50-200 | 200-400 | 400-630 |

| Water pump | 3kw | 4kw | 5.5kw | 5.5kw X 2pcs | 7.5kw X 2pcs |

| Vacuum pump | 2.2kw X 2pcs | 4kw | 4kw | 4kw X 2pcs | 7.5kw 5.5kw X 2pcs |

| Caliber Length(mm) | 5000 | 6000 | 6000 | 8000 | 6000, 3000 |

| Water cooling tank | No | No | 5000 | 6000 | 100000 |

| Hauling motor | 0.75kw 4pcs | 2.2kw | 3.7kw | 7.5kw | 18.5kw |

| Hauling belt | 4pcs | 2pcs | 2pcs | 4pcs | 6pcs |

| Cutting motor | 1.1kw 2pcs | 2.2kw | 3.7kw | 3.7kw | 3.7kw |

| Inverter brand | ABB | ABB | ABB | ABB | ABB |

| Contactor brand | Schneider | Schneider | Schneider | Schneider | Schneider |

| Temperature brand | OMRON | OMRON | OMRON | OMRON | OMRON |

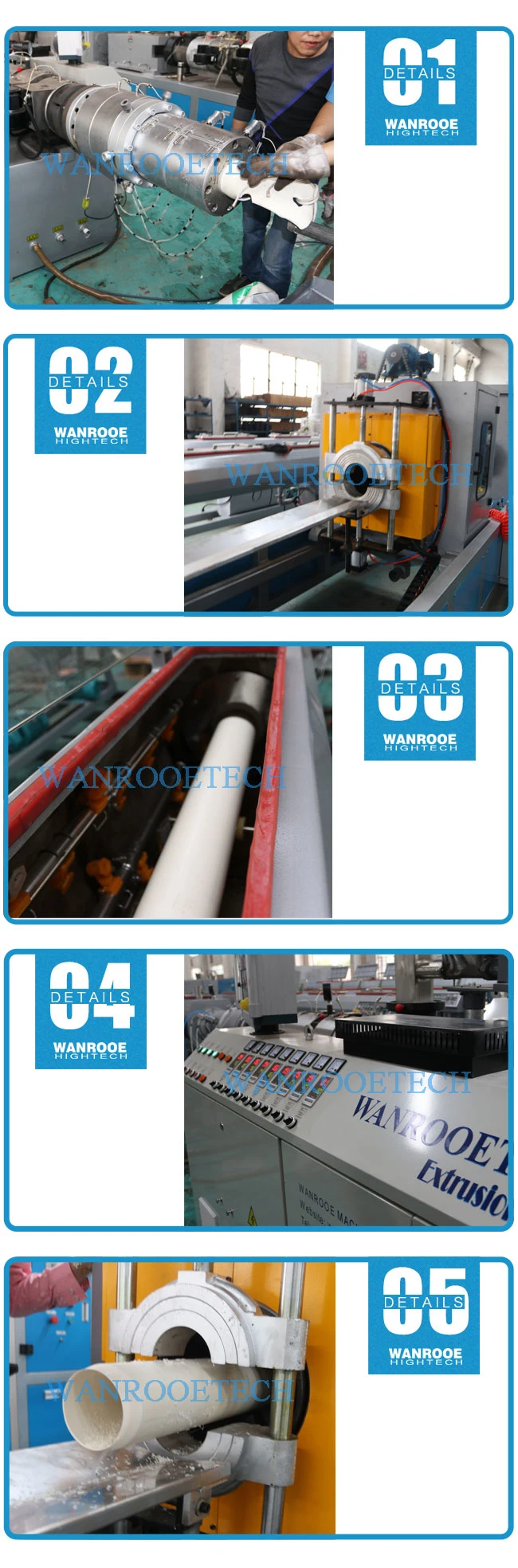

Details

Conical Twin Screw Extruder

A: Counter Rotating Conical twin screw machined on CNC make thread milling machines by simulation software for better performance.

B: Conical twin screw extruder is specially designed for high calcium loading.

C: Compact & reliable gear box

D: Synchronized drives of the extruder, feeder, and haul-off enable the ease of operation. It is designed for high output at low screw speed and less power consumption.

E: Bi-metallic screw & barrel can be provided for two -three times more lifespan than nitrided screw and barrel.

Die Head

A: Die head is made of high carbon content forgedalloy steel for better life and performance.

B: It has resonable flow channel design and special treatment on the surface;

C: Special flow channel design ensures the equal distribution of PVC in the mould;

D: Melt temperature and pressure remain even.

Spraying Bath

A: Intensive cooling of the pipe with the help of number of spraying nozzles;

B: Axial adjustment of thank on slide rails with locking arrangement;

C: Self cleaning type spray nozzle with wide opening for intensive cooling of the pipe;

D: Acrylic transparent cover for easy inspection.

Pneumatic Haul Off

A; Twin and multi-track system;

B: Track can be adjusted for different sizes of pipe ranging between 20mm and 800mm;

C: Hall-off is synchronized with extruder with the help of AC frequency variable drive;

D: Gap between two tracks and pressure is adjusted pneumatically;

E: V-Groove rubber pads mounted on chain with proper tensioning to prevent ovality for large even for large diameter and think wall pipes.

Planetary Cutting saw

A: Planetary saw blades cutting for pipe diameter up to 800mm;

B: Rotary cutting make sure smooth and clean;

C: Cutting is PLC controlled;

D: Saw dust powerful sucking device

E: Special hard alloy saw blade is employed to cut heavy caliber thick wall pipes.