HDPE PE Gas supply pressure pipe making machine 16mm-1600mm.

PE Casing pipe making amchine.90mm-1600mm.

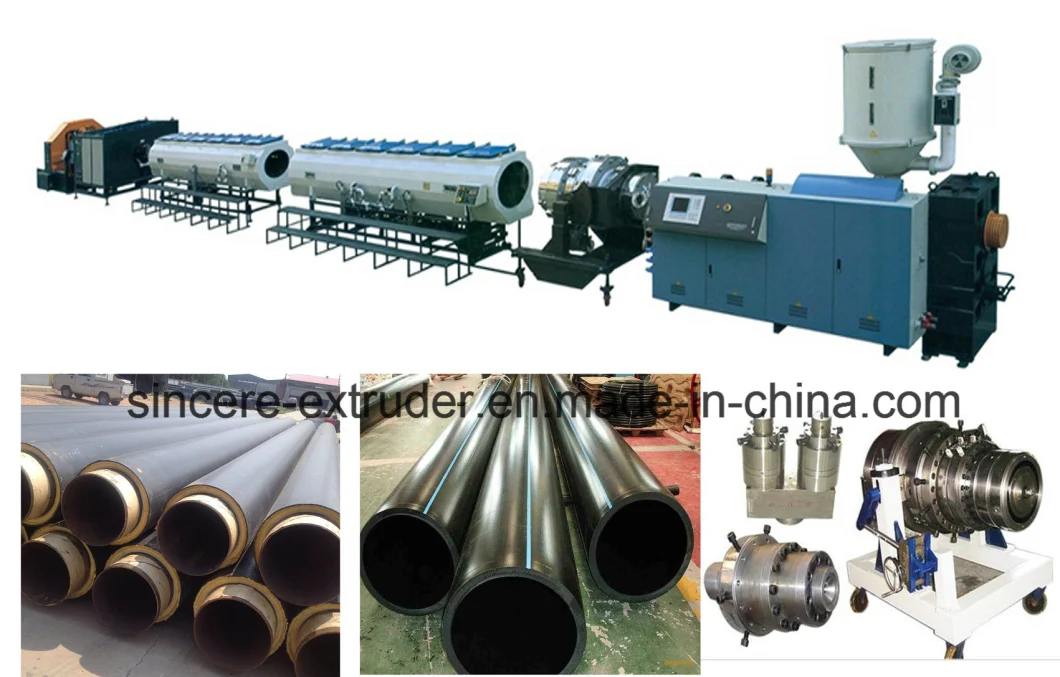

1.hdpe pipe extrusion machine/line process flow:

Vacuum loader → Hopper dryer→ Single screw extruder → PE pipe mould and co-extruder→ Vacuum calibration tank→Spray cooling tank → Hauling off machine → No chip cutting machine or Planetary cutting machine → Pipe winding machine or pipe stacker.

2.hdpe pipe extrusion machine/line applications

PE pipe machine is mainly used to manufacturing PE plastic pipe, and GF series tube auxiliary equipments can also use to process oher plastic Extruder and GF series tube auxiliary equipments take the features of advanced, reliable & applied together, and provide strong certification for high-quality tube for customers

This Large diameter HDPE/MDPE fuel gas/water supply pipe extrusion line is mainly used for producing large diameter HDPE/MDPE pipe. The pipe has some excellent features such as heating resistant, aging resistant, high mechanical strength, environmental stress cracks resistant, good creep resistant, etc. It is a preferred gas conduit for ductwork systems between city and its suburb, water supply in city.3. Production line features:

High efficiency extruder is designed for HDPE pipe, equipped with reducer which is high speed and low noise, feeding section with cooling unit and reversing spiral groove, different pitch undulant screw which allows great output, lower melting temperature, and lower energy consumption.

Distributed spiral composite extrusion die-head ensures the melting pressure and flux even and stable, the surface of pipe smooth and glossy. Co-extruder for Marking strip.

Vacuum calibration and spray water cooling tank made of stainless steel ensures precise calibration and fast cooling.

Adopts multi claws haul-off unit, speed adjusted by frequency inverter.

Equipped with planetary cutter. Be able to cut large diameter and thick wall pipe.

Equipped with Pipe stacker

Final product

4. Technical Parameters:

| Model | Pipe Diameters(mm) | Supporting extruder | Extrusion capacity(kg\h) | Total Installed Power(kw) |

| SG-63 | 16-63 | SJ65\33 SJ25\25 | 120-180 | 110 |

| SG-110 | 16-110 | SJ65\33 SJ25\25 | 150-200 | 130 |

| SG-160 | 50-160 | SJ75\33 SJ25\25 | 150-220 | 150 |

| SG-250 | 75-250 | SJ75\33 SJ25\25 | 280-350 | 280 |

| SG-315 | 110-315 | SJ90\33 SJ25\25 | 250-350 | 350 |

| SG-450 | 160-450 | SJ90\33 SJ25\25 | 350-450 | 400 |

| SG-630 | 315-630 | SJ120\33 SJ25\25 | 550-850 | 550 |

| SG-800 | 450-800 | SJ150\33 SJ25\25 | 800-1300 | 750 |

| SG-1000 | 600-1000 | SJ150\33 SJ25\25 | 800-1300 | 750 |

| SG-1200 | 800-1200 | SJ120\33*2 SJ25\25 | 950-1600 | 950 |

| SG-1600 | 1000-1600 | SJ150\33*2 SJ25\25 | 1500-2500 | 1300 |

5. Contact:

Ekaterina Sun

Mobile: +8615726275773