PVC Pipe Extrusion Machine/CPVC pipe making machine/PVC pipe machine

Machine introduce:

PVC/UPVC pipe extrusion machine is mainly used in the area of agricultural water supply system, architectural water supply and drainage system, conduit cable, etc. As well as PVC pipe material of all sorts of pipe caliber and wall thickness.

This PVC pipe making line mainly consists of conical twin screws extruder, vacuum calibrating tank, haul-off unit, cutting unit, stacker, etc. The extruder and haul-off unit have applied ABB brand inverter. The haul off machine includes two-claw type, three-claw type, four-claw type, six-claw type, eight-claw type, etc.

Saw cutting or planet cutting can be applied, it is additionally applied with length measuring meter and thickness increasing device.

2. Register and record customer information

3. Offer spare parts

4. Provide with necessary technical support for new application

5. Visit customer regularly and correct information

Why choose us:

1. Lower investment cost for a high quality and durable machine;

2. Low energy consumption with high production output;

3. Overseas installation and training are available;

4. Machine warranty with spares in stocking and in-time delivery;

5. Fast machine delivery and installation: KWELL produces on an average of 10 sets of plastic machines per month and can deliver the machine faster than most manufacturers. The regular delivery time of an KWELL recycling machine is 35 days.

Please convenient yourselves by me !!

http://kwellgroup.en.made-in-china.com/

Machine introduce:

PVC/UPVC pipe extrusion machine is mainly used in the area of agricultural water supply system, architectural water supply and drainage system, conduit cable, etc. As well as PVC pipe material of all sorts of pipe caliber and wall thickness.

This PVC pipe making line mainly consists of conical twin screws extruder, vacuum calibrating tank, haul-off unit, cutting unit, stacker, etc. The extruder and haul-off unit have applied ABB brand inverter. The haul off machine includes two-claw type, three-claw type, four-claw type, six-claw type, eight-claw type, etc.

Saw cutting or planet cutting can be applied, it is additionally applied with length measuring meter and thickness increasing device.

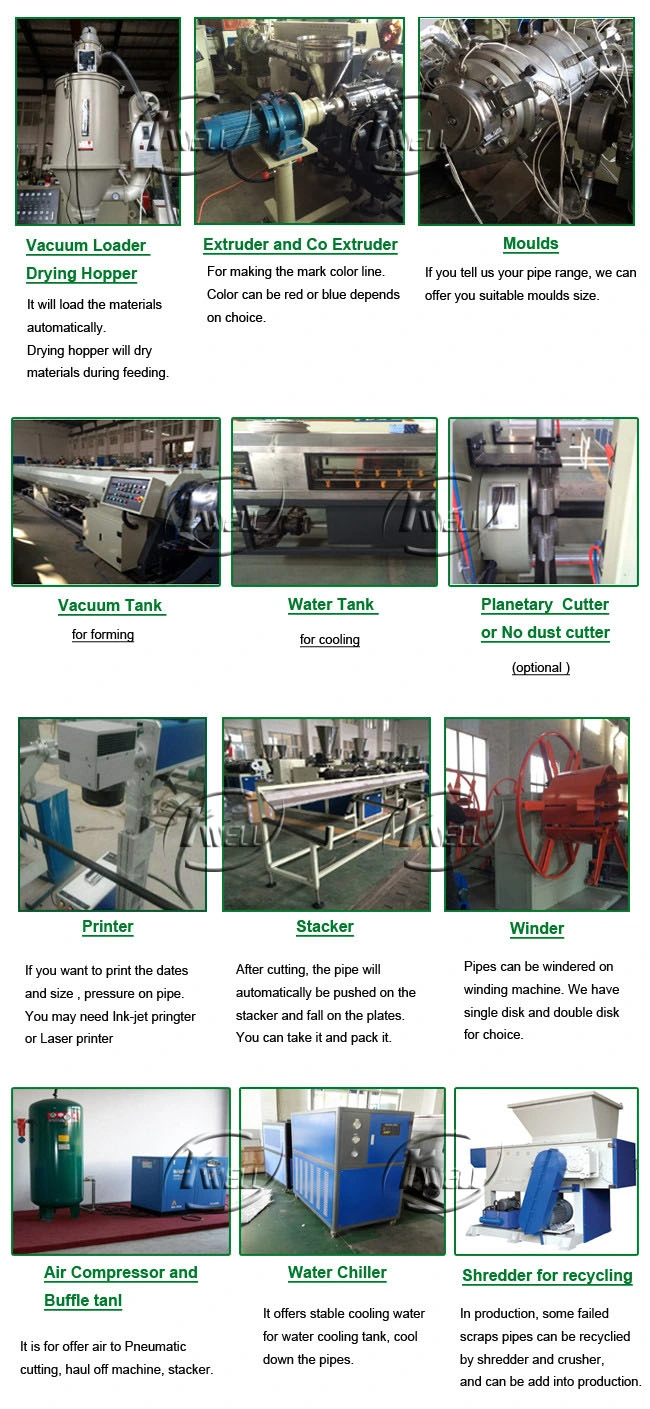

Machine Process Flow:

| Item | Quantity |

| Conical twin screw extruder (Equipped with automatic feeding unit) | 1set |

| Die and Mold | 1set |

| Vacuum calibration unit | 1set |

| Haul-off unit | 1set |

| Cutter Unit | 1set |

| Stacker | 1set |

Machine Main Technical Parameters:

| Model | PVC-2-50 | PVC-4-25 | PVC-110 | PVC-160 | PVC-250 | PVC-315 | PVC-400 | PVC-630 |

| Extrusion machine | SJZ51/105 | SJZ65/132 | SJZ51/105 | SJZ65/132 | SJZ65/132 | SJZ80/156 | SJZ80/156 | SJZ92/188 |

| Pipe diameter scope(mm) | Φ16-Φ50 | Φ16-Φ50 | Φ20-Φ110 | Φ50-Φ160 | Φ50-Φ250 | Φ110-Φ315 | Φ160-Φ400 | Φ315-Φ630 |

| Vacuum shaping box length(mm) | 4000 | 4000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

Haul-off speed (m/min) | 1.2-12 | 1-10 | 0.6-6 | 0.5-5 | 0.4-4 | 0.3-3 | 0.2-2.5 | 0.2-1.5 |

| Installed capacity(kw) | 67 | 85 | 67 | 85 | 95 | 125 | 135 | 255 |

| Total length(mm) | 17000 | 18000 | 17000 | 18000 | 20000 | 20500 | 28000 | 30000 |

Machine pictures for reference:

Machine Packing details:

After-sale:

2. Register and record customer information

3. Offer spare parts

4. Provide with necessary technical support for new application

5. Visit customer regularly and correct information

Why choose us:

1. Lower investment cost for a high quality and durable machine;

2. Low energy consumption with high production output;

3. Overseas installation and training are available;

4. Machine warranty with spares in stocking and in-time delivery;

5. Fast machine delivery and installation: KWELL produces on an average of 10 sets of plastic machines per month and can deliver the machine faster than most manufacturers. The regular delivery time of an KWELL recycling machine is 35 days.

Please convenient yourselves by me !!

http://kwellgroup.en.made-in-china.com/