| name | High wear resistance100 virgin black uhmwpe pe sheet |

| Material | PA, NYLON, UHMWNPE, HDPE, POM, PP, PU, PET PEEK, etc. |

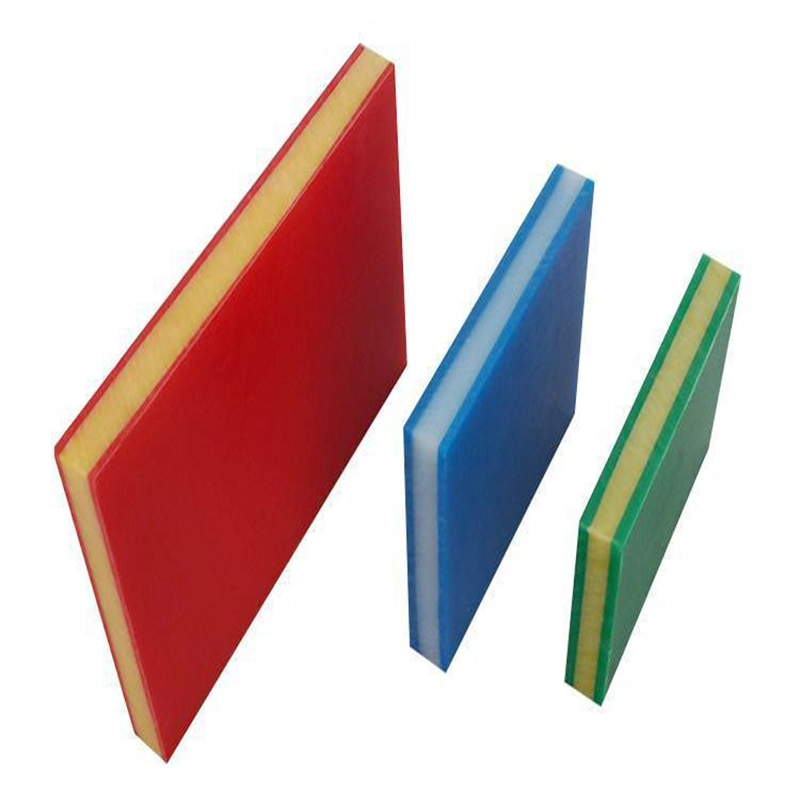

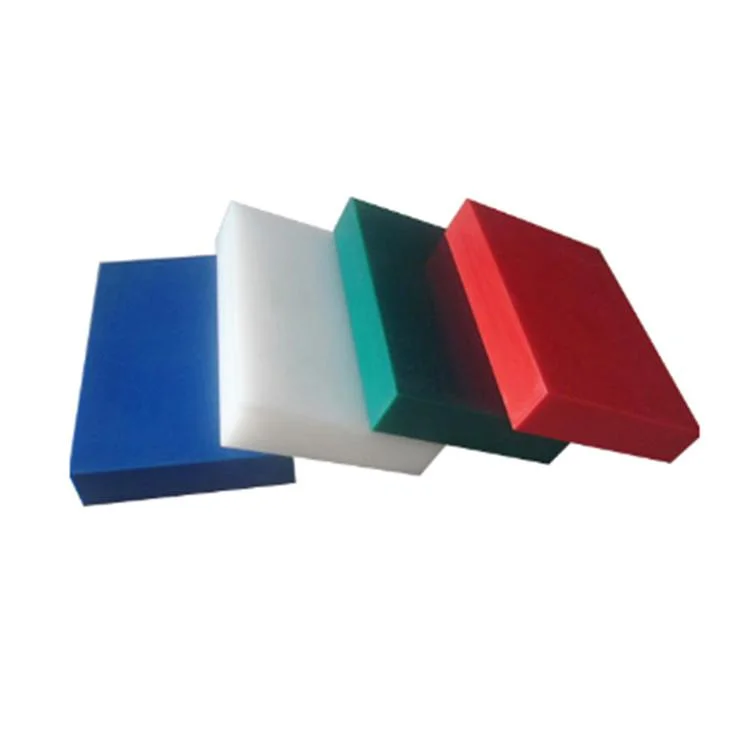

| colour | white/yellow/blue/green/black and so on |

| performance | UV Stabilized, Corrosion resistance, impact resistance, low water absorption, good self - lubricating property |

| size | 1240mm*4040mm*(1-300) mm 2030mm*3030 mm*(1-300) mm |

| Logo | Yes |

| OEM | Yes |

| Samples Time | 5~10 days |

| Certification available | ISO9001, SGS, Test Report, RoSH |

| Packing Details | Pallet with strech film, customised wooden case, carton, or others as request. |

| Production Capacity | 10 Tons Per Day |

| Advantage | Self-lubricating properties superior,Strong corrosion resistance, high chemical technical, non-stick phase is not easy to attach the product surface and other materials. |

| No. | Item | Unit | Test Standard | Result |

| 1 | Density | g/cm3 | GB/T1033-1966 | 0.91-0.96 |

| 2 | Molding shrinkage % | ASTMD6474 | 1.0-1.5 | |

| 3 | Elongation at break | % | GB/T1040-1992 | 238 |

| 4 | Tensile strength | Mpa | GB/T1040-1992 | 45.3 |

| 5 | Ball indentation hardness test 30g | Mpa | DINISO 2039-1 | 38 |

| 6 | Rockwell hardness | R | ISO868 | 57 |

| 7 | bending strength | Mpa | GB/T9341-2000 | 23 |

| 8 | Compression strength | Mpa | GB/T1041-1992 | 24 |

| 9 | Static softening temp. | ENISO3146 | 132 | |

| 10 | Specific heat | KJ(Kg.K) | 2.05 | |

| 11 | Impact strength | KJ/M3 | D-256 | 100-160 |

| 12 | heat conductivity | %(m/m) | ISO11358 | 0.16-0.14 |

| 13 | sliding properties and friction coefficient | PLASTIC/STEEL(WET) | 0.19 | |

| 14 | sliding properties and friction coefficient | PLASTIC/STEEL(DRY) | 0.14 | |

| 15 | Shore hardness D | 64 |

Excellent properties for UHMWPE

| 1.Abrasive resistance which always have in thermoelectricity polymer. |

| 2.Best shock resistance even in low temperature. |

| 3.Low frictional factor, and well sliding bearing material |

| 4.Lubricity ( no caking, in adhesion) |

| 5.Best chemical corrosion resistance and stress craze resistance |

| 6.Excellent machinery process ability |

| 7.Lowest water absorption(<0.01%) |

| 8.Paragon electric insulativity and antistatic behavior |

| 9.Nice high energy radioactive resistance |

| 10.Density is lower than other thermoplastics (< 1g/cm3) |

| 11.Long using temperature range: -269°C--90°C |

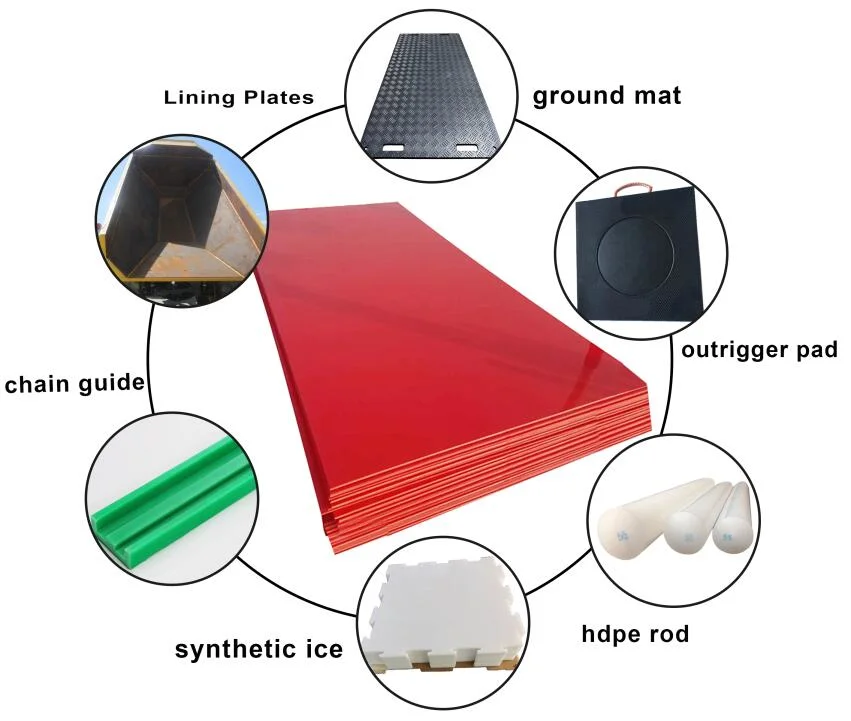

Tianjin Beyond Technology Developing Co., Ltd is a comprehensive plastic processing and trading company, engaged in the research and development and production of industrial sheet and plastic processing part for more than 10 years.

We have established long-term and stable cooperative relations with domestic companies, and our products have exported to Europe, North America, Southeast Asia, South America, Australia and other countries

Our main products: HDPE, UHMWPE, MC nylon, PA, POM, PP, PVC material sheet and plastic processing part.

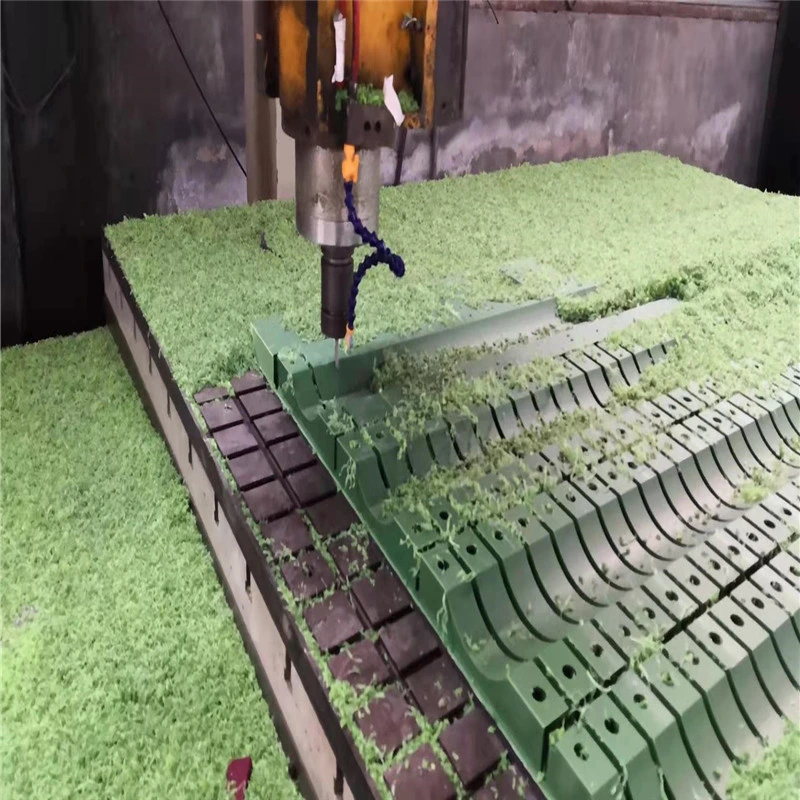

Tianjin Beyond Technology Developing Co., Ltd has multiple production lines, including CNC machine 6 lines, CNC milling machines 7 lines, extruder machines 4 lines, injection mold machines 3 lines, Molded sheet machines 2 lines etc. And we have an experienced & skilled production team. To guarantee the quality, we have specialized QC team to suspect every step. A strong consulting and after-sales service team to make you rest assured to cooperate with us.

· If you have any need and contact our,we will reply you within 6 hours.

· You buy our products and we will give you competitive price.

· we cooperate with professional logistics companies to provide efficient goods transports such as sea,air and land transports to customers.

· We can process with supplied drawing.

· We have lots of stock.

1.Q:Which kind of product can you do?

A:Plastic extrude sheet plastic mouled sheet plastic injection molding part and plastic cnc machining part .

2.Q:What kind of plastic products can your factory make?

A:custom UHMWPE,HDPE,PA,Nylon,POM,,PP,ABS,PTFE and so on.

3.Q: Which kind information need for quotation?

A:1) Sample photo with size or 2D/3D design

2) Product material

3) The quantity

4) Runner type, cold or hot

5) Mould steel type, P20, 718, 2738, H13, S136, 2316, an so on.

4.Q:I have no 3D drawing, how should I start the new project?

A:You can supply us a sample or tell me your idea,we will help to finish the 3D drawing design.

5.Q:How long will be the injection mold finished?

A:Usually it will take about 15 days to finish the mold.

6.Q:How about the samples?

A:After mold finished, We will make some samples for you to check as soon as we finish the mold and then deliver the samples for you to check.

7.Q:How about the proprietary rights of the plastic injection mold?

A:Customer paid the mould so it all belong to Customer.