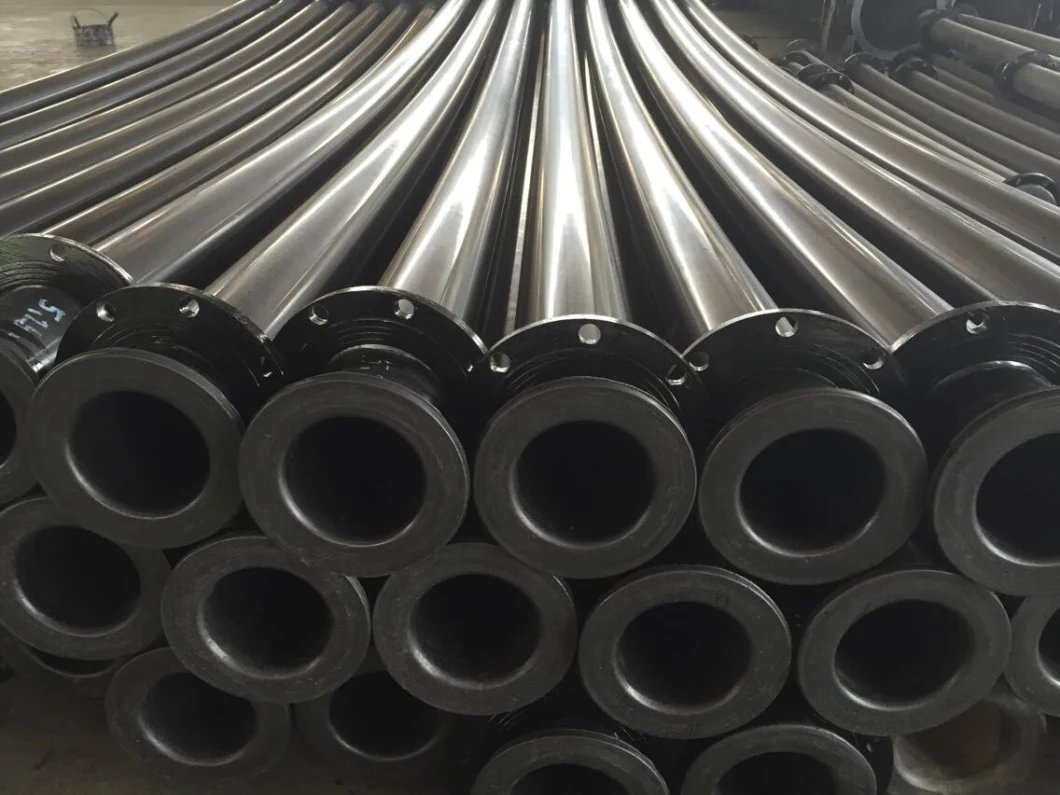

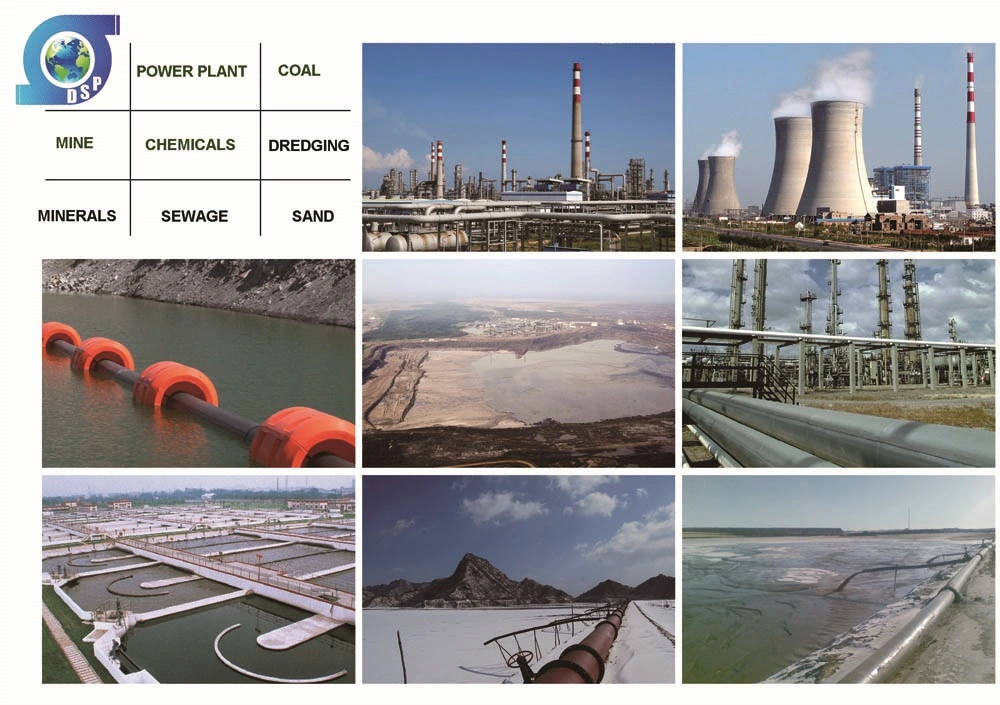

Ultra High Molecular Weight Polyethylene Marine Sand Dredger UHMWPE Pipe

Mating Pipelines for Sand/Gravel/Dredger/Slurry Pump:

Mating Pipelines for Sand/Gravel/Dredger/Slurry Pump:

Introduction:

Ultra-high Molecular Weight Polyethylene (UHMWPE) , which refers to the molecular weight of more than 2.5

million(The common polyethylene product is about 200~300 thousand), has the development priority from the

China National Ministry of Science and Technology. High molecular weight gives it exceptional working

performance, excellent anti-abrasive, anti-corrosive, self-lubricating, impact resistant, uvioresistant, the unique

low temperature resistance and good chemical stability, which is one of best of the existing engineering plastics,

internationally known as the "very magical material."

Characteristics:

1. Excellent wear resistance.

UHMWPE wear resistance ranks first all plastic material, 66 times than nylon, 4 times than polytef, 9 times than

rdinary polyethylene, even more than ordinary metals, is 7 times than that of carbon steel, and 10 times than

stainless steel, greatly improved the service life.

2. Light weight. The density UHMWPE is about 0.94g / cm3, lower than other engineering plastics, 1/2 lighter

than polytef, 1/7 light of the steel pipe, thus easy for installation, reducing the energy consumption.

3.The UHMWPE pipe has good flexibility, tension, strength and elasticity. It doesn't break after folding, extruding

or internal or external force impact. The pipes are connected directly and can be bended in water. The bending

degree of 4 to 8 pcs of pipes can be 360 degree. It is of good resistance of storm and waves. On land, the pipes

can be connected even in area with 30 degree unevenness.

4. Self-lubricating. The friction of UHMWPE is very low and good self-lubricating performance, better than other

metal pipelines.

5 Chemical resistance. UHMWPE has the high chemical stability and anti-corrosive ability in the certain range of

temperature and concentration ability of various of corrosive media (acids, bases, salts) and organic media.

6. Lower water absorption. UHMWPE is almost non-absorbent, does not swell in water, much less absorbent than

ylon.

7. Non-stick performance. The UHMWPE surface is very weak, almost equal to PTFE, thus no scale deposit at

the pipe surface.

8. Excellent impact resistance. UHMWPE has the superb impact resistance, 2 times better than polycarbonate.

Even in the ammonia temperature (-269 ºC), it can still maintain good impact resistance, which make it a wide

application in cryogenic engineering field.

9. Good sanitation. UHMWPE meet the national health standard, even up to the standard of human-contact field.

In addition, UHMWPE also has excellent ability of cracking-resistance, electrical insulation-resistance, fatigue-

resistance, deformation-resistance under high temperature, γ-rays-resistance and other superb characteristics.

UHMWPE Pipe Parameters:

| Diameter MM | 0.6Mpa | 0.8Mpa | 1.0Mpa | 1.25Mpa | 1.6Mpa | 2.0Mpa |

| Thick(MM) | Thick(MM) | Thick(MM) | Thick(MM) | Thick(MM) | Thick(MM) | |

| 65 | 8 | 9 | ||||

| 96 | 9 | 10 | ||||

| 110 | 8 | 10 | ||||

| 130 | 8 | 10 | 12 | |||

| 159 | 10 | 12 | 15 | |||

| 168 | 8 | 10 | 13 | 16 | ||

| 205 | 8 | 10 | 12 | 15 | 18 | |

| 219 | 9 | 11 | 13 | 16 | 20 | |

| 236 | 10 | 12 | 14 | 18 | 22 | |

| 250 | 10 | 12 | 15 | 19 | 23 | |

| 273 | 9 | 11 | 13 | 16 | 21 | 25 |

| 280 | 9 | 11 | 14 | 17 | 21 | 26 |

| 300 | 10 | 12 | 15 | 18 | 23 | 27 |

| 315 | 10 | 12 | 15 | 19 | 24 | 29 |

| 325 | 10 | 13 | 16 | 19 | 24 | 30 |

| 350 | 11 | 14 | 17 | 21 | 26 | 32 |

| 377 | 12 | 15 | 18 | 22 | 28 | 35 |

| 400 | 12 | 16 | 19 | 24 | 30 | 36 |

| 415 | 13 | 16 | 20 | 25 | 31 | |

| 426 | 13 | 17 | 20 | 25 | 32 | |

| 536 | 16 | 21 | 26 | 23 | ||

| 560 | 16 | 22 | 27 | 33 | ||

| 630 | 19 | 25 | 30 | 37 | ||

| 652 | 20 | 26 | 32 | 38 | ||

| 710 | 21 | 27 | 34 | |||

| 800 | 23 | 31 | 38 |

II. Floaters

Product Introduction:

The hull of floater frame is made from medium density polyethylene material with excellent flexibility, filled with high strength polyurethane foam inside. With reasonable structure and good performance, the floater becomes the ideal substitution of the traditional steel floater for the floating dredging pipes.

The GI bolts and washers will be provided free.

Chracteristics:

A. The floating frame is equipped with shock and wave resistance, compact and reasonable structure, easy installation and excellent performance. Being floating materials for mud delivery pipeline on water, it becomes the first choice of dredging customers.

B. Good Toughness, strong environmental stress cracking resistance (ESCR), and being appropriate for offshore and lake construction.

C. Light weight, high resistance to wear, being convenient to install and transport, and low cost of transportation and transformation.

D. Resistance to corrosion and climate, 3 times more than steel buoy in terms of life span.

E. Easy, fast and flexible assembling diversified modeling.

F. Low price and cost performance is significantly better than that of steel buoy.

G. Being popular with customers because of its consistent quality, novel modeling reasonable price and excellent service.

H. Light weight, big Buoyancy.

I. resistance to impact, and acid-proof alkaline, anti-corrosive etc

J. very low absorption rate

D. Simple installation and low maintenance costs

E. service temperature range-60°C-80°C

| Pipe ID (mm) | Pipe Thickness(mm) | Floating body I.D(mm) | Floating body O.D(mm) | Floating body Length(mm) | Floating Body Wall Thickness(mm) | net Bouyancy ( kg/ pair) |

| 300 | 6 | 330 | 1000 | 1000 | 6 | 500 |

| 350 | 6 | 380 | 1100 | 1100 | 6 | 550 |

| 414 | 6 | 430 | 1200 | 1200 | 6 | 1200 |

| 450 | 9 | 480 | 1300 | 1300 | 7 | 1250 |

| 500 | 9 | 530 | 1300 | 1500 | 8 | 1350 |

| 550 | 9 | 580 | 1400 | 1600 | 8 | 1600 |

| 600 | 10 | 630 | 1480 | 1600 | 8 | 1950 |

| 650 | 12 | 680 | 1550 | 1800 | 8 | 2200 |

| 700 | 12 | 730 | 1620 | 1900 | 9 | 2300 |

| 750 | 12 | 780 | 1700 | 2000 | 9 | 2700 |

| 800 | 14 | 840 | 1850 | 2100 | 12 | 3200 |

| 850 | 16 | 890 | 2000 | 2400 | 12 | 4600 |

| 900 | 16 | 940 | 2040 | 2500 | 13 | 4900 |

| 1100 | 25 | 1150 | 2400 | 2600 | 14 | 6500 |

III. Flexible Rubber Hose

1)Discharge Rubber Hose

Hose Inner Diameter: 50mm--1000mm,

Working Pressure: 5-30 bar,

Length: 1-10 meters/piece,

It is used for connecting with dredging PE Pipe or Steel pipe, reduce the swaying which is caused by waves,

so that pipes will be well protected and medium can flow smoothly in the pipeline.

| Hose I.D. (mm) | Length (Meter) | Working Pressure | Hose I.D. (mm) | Length (Meter) | Working Pressure | ||

| 200 | 1 | 5-30 bar | 600 | 1.5 | 5-30 bar | ||

| 250 | 1 | 5-30 bar | 650 | 1.6 | 5-30 bar | ||

| 300 | 1.2 | 5-30 bar | 700 | 1.7 | 5-30 bar | ||

| 350 | 1.2 | 5-30 bar | 750 | 1.8 | 5-30 bar | ||

| 400 | 1.2 | 5-30 bar | 800 | 1.8 | 5-30 bar | ||

| 450 | 1.3 | 5-30 bar | 850 | 2 | 5-30 bar | ||

| 500 | 1.5 | 5-30 bar | 900 | 2 | 5-30 bar | ||

| 550 | 1.5 | 5-30 bar | 1000 | 2.5 | 5-30 bar | ||

| Other sizes of hose can be made upon request. | |||||||

2)Suction Dredging Rubber Hose:

Structure:

1. Tube: Black abrasion resistant Natural Rubber

2. Reinforcement: Multiple plies of polyester fabric with spring steel helix wire, or within strengthened steel loop

inside.

3. Cover: Neoprene

Suction hose is used with dredger for silt/gravels conveyance. It sucks up the mixture of silt and water using negative pressure. Mostly used with these hoses are the rubber flange/steel backing flange and the Double Action flange. They can be supplied in any size, and depending on application, with 100% vacuum capability and high implosion pressures. For use with gimbals and in the ladder of cutter dredgers we can equip them with small bending radius suction hoses.

Welcome to contact us any time for details.

Your inquiry will get our prompt attention and response !