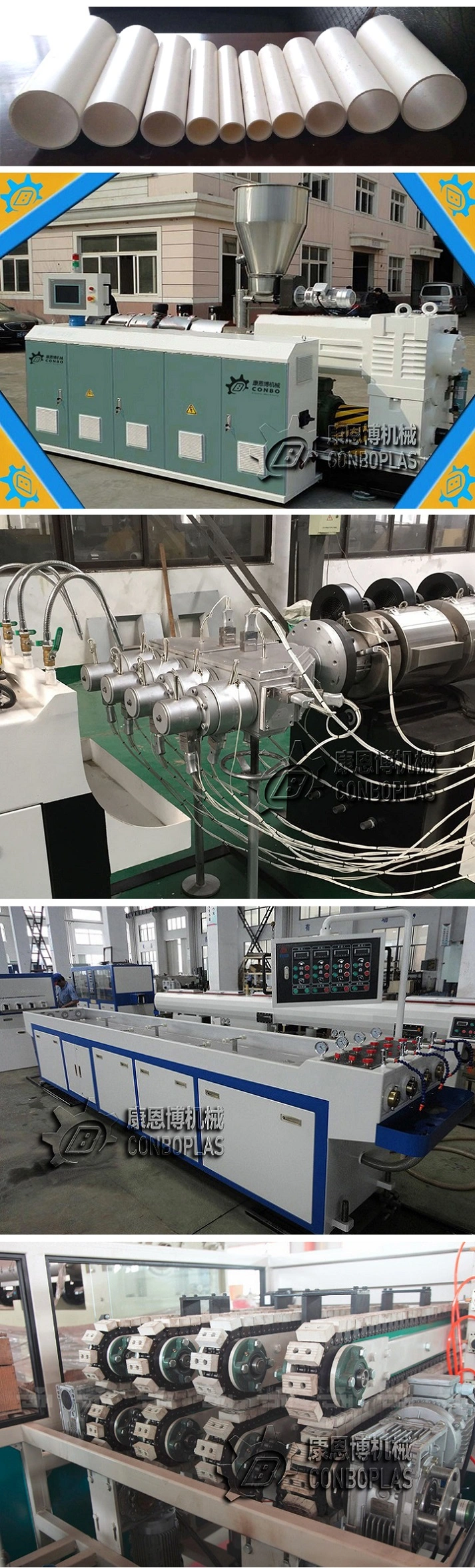

PVC Electrical Conduit pipe Production Line:

Brief Introduction:

Pipes made from PVC are usually manufactured by extrusion.This process starts by feeding plastic material from a hopper into the barrel of the extruder.The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel.The molten polymer is then forced into a die,which shapes the polymer into a pipe that hardens during cooling.

The main machine is SJSZ51/105 or SJSZ65/132 conical twin screw extruder. This equipment can manufacture double pipes at the same time.The pipe diameter is 16-63mm.This pipe production line can avoid the condition when one tube is adjusted and the other one is affected.Even if it produces small diameter pipe, it can also achieve great output.

The pipe extrusion line adopts humanization design and automatic control system, which can realize the full automatic processing and reduce default in operation.We manufacture competitive and reliable plastic extrusion machinery for pipes using PVC. The machine is well manufactured with superior technique to provide you the best of output with very maximum utilization of resources.

Technical Specifications:

Remarks: all the information above is only for reference, please gather the exact data by contacting us.

ELECTRICAL COMPONENTS QUALITY:

AUXILIARY MACHINES:

CONTACT INFORMATION:

Manager: BOSH LEUNG (MR.)

Tel/Fax: +86-512-58951481

Mobile:+8615262324740

Company website: http://conboplas1986.en.made-in-china.com

Address: Leyu Development Zone, Zhangjiagang city, Jiangsu Province, China.

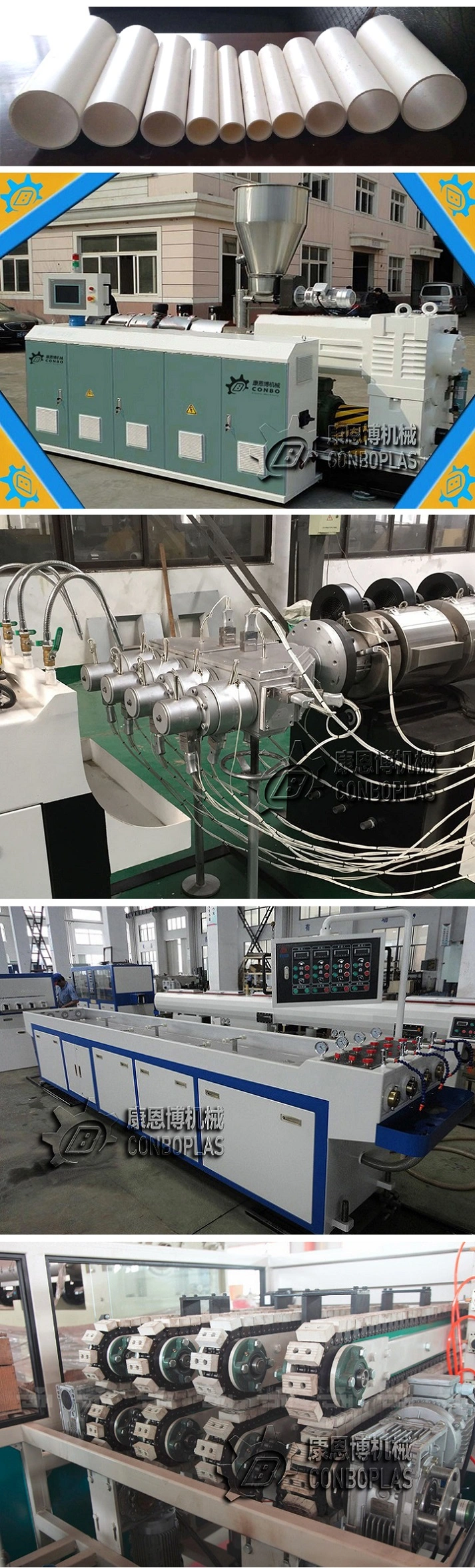

Brief Introduction:

Pipes made from PVC are usually manufactured by extrusion.This process starts by feeding plastic material from a hopper into the barrel of the extruder.The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel.The molten polymer is then forced into a die,which shapes the polymer into a pipe that hardens during cooling.

The main machine is SJSZ51/105 or SJSZ65/132 conical twin screw extruder. This equipment can manufacture double pipes at the same time.The pipe diameter is 16-63mm.This pipe production line can avoid the condition when one tube is adjusted and the other one is affected.Even if it produces small diameter pipe, it can also achieve great output.

The pipe extrusion line adopts humanization design and automatic control system, which can realize the full automatic processing and reduce default in operation.We manufacture competitive and reliable plastic extrusion machinery for pipes using PVC. The machine is well manufactured with superior technique to provide you the best of output with very maximum utilization of resources.

Technical Specifications:

| Model | Extrusion type | Screw diameter (mm) | Pipe range (mm) | Capacity (kg/h) | Main motor power (kw) | Line length (m) |

| GF25 | Four-out | 65/132 | 16-25 | 120-250 | 37 | 25 |

| GF63 | Double-out | 65/132 | 16-63 | 120-250 | 37 | 25 |

ELECTRICAL COMPONENTS QUALITY:

AUXILIARY MACHINES:

CONTACT INFORMATION:

Manager: BOSH LEUNG (MR.)

Tel/Fax: +86-512-58951481

Mobile:+8615262324740

Company website: http://conboplas1986.en.made-in-china.com

Address: Leyu Development Zone, Zhangjiagang city, Jiangsu Province, China.