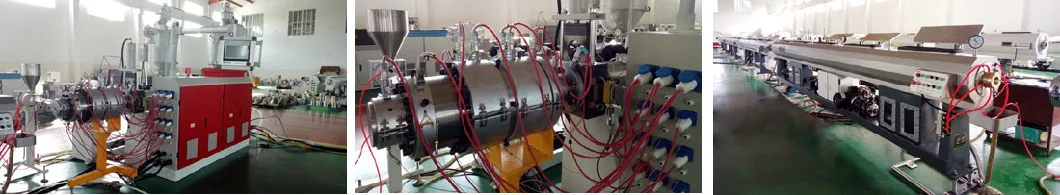

The HDPE pipe production line adopts specially designed high efficient five-section type screw andbarrel, independently designed by KAIDE company. Which is the essential conditions for the rapid materials plasticizing & dispersion in high output production.

The HDPE pipe production line adopts specially designed high efficient five-section type screw andbarrel, independently designed by KAIDE company. Which is the essential conditions for the rapid materials plasticizing & dispersion in high output production.

Technical Data

| Line Model | Screw Diameter | L/D | Production Scope | Production Speed | Nominal Power |

| SJ-60 | Ф60mm | 36:01:00 | ф75-160mm | 1-10m/min | 145KW |

| SJ-80 | Ф80mm | 33:01:00 | ф110-315mm | 0.8-8m/min | 186KW |

| SJ-90 | Ф90mm | 33:01:00 | ф200-450mm | 0.2-2m/min | 250KW |

| SJ-90 | Ф90mm | 36:01:00 | ф315-630mm | 0.2-1m/min | 442KW |

Die Head

The HDPE pipe making machine use spiral diehead, which ensures the stability of high speed extrusion and manufactured pipe quality.

Gravimeter System

(1)High precise Gravimeter control system is applied in this HDPE Pipe line.

(2)It is used formeasuring & calculating and precise control of pipe weight per meter andits extrusion output

(3)The application of this system can shorten thestart-up time, improve the produced pipe quality, and save raw material.

PLC Control System

The HDPE pipe extrusionmachine adopts new generation Siemens PLC programmable computer control system,which could ensure the whole line high synchronous control and its stable &reliable running.

Generally, we often contact with HDPE pipes it has been used for 50 years in developed countries such as Germany, Japan, South Korea and so on. As a new building material widely used in domestic municipal pipelines, which industries are PE pipes mainly used in?

Generally, we often contact with HDPE pipes it has been used for 50 years in developed countries such as Germany, Japan, South Korea and so on. As a new building material widely used in domestic municipal pipelines, which industries are PE pipes mainly used in?1) Urban and rural water pipe system

PE pipe is hygienic, non-toxic and non scaling, which is more suitable for urban and rural water supply trunk pipe and buried pipe. It is safe, hygienic, economical, convenient for construction and has long service life.

2)Urban gas pipeline:Because PE pipe has better creep resistance and economy, it can gradually replace ductile iron pipe for urban gas transmission.

3)Replaceable cement pipe, cast iron pipe and steel pipe

It can be widely used in the old city network reconstruction project, without large area excavation, convenient construction and low cost.

4) Industrial raw material pipeline

It can be used in chemical industry, chemical fiber, food, forestry, pharmacy, light industry, papermaking, metallurgy and other industries.

5) Landscape water supply network

Landscaping needs a large number of water pipes, and the flexibility and low cost of PE pipe make it the best choice.

6) Pipes for sewage discharge

PE pipe has unique corrosion resistance, can be used for industrial wastewater, sewage discharge, low cost and maintenance.

For more information, please feel free to contact us !